Powder coating on our in-house line at EICA

As a family-owned company with roots dating back to 1957, we offer powder coating on a modern in-house line where every step – from design and cutting to final assembly – takes place under one roof. This gives you short lead times, full traceability, and a surface finish that withstands tough industrial environments.

Why choose EICA for powder coating?

- End-to-end flow: laser cutting, punching, bending, welding and powder coating with no middlemen.

- Flexible batch sizes: from single prototypes to medium-sized series.

- Wide range of materials: stainless steel, aluminium and mild steel – all with equally high finish.

- Quality & environment: documented policies drive continuous improvements.

The powder coating process step by step

Pre-treatment and precision

Every part is carefully pre-treated before powder coating to ensure optimal adhesion and corrosion protection.

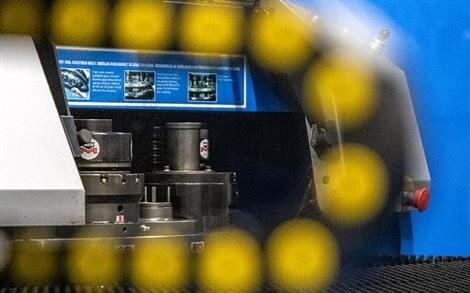

Electrostatic application

The powder is applied electrostatically in a controlled environment, which minimizes waste and ensures even coverage.

Curing and final inspection

After curing in the oven, the surface is inspected both visually and with measurements to verify that color, gloss and coating thickness meet your specifications.

Capacity and materials

Our line handles items up to 2.5 m × 1.4 m × 0.8 m. By combining powder coating with TIG/MAG welding and CNC machining, we can deliver complete chassis, hygiene-critical components and ergonomic furniture.

Typical applications

- Patient-near hospital furniture

- Height-adjustable workstations

- Stainless components for the food industry

- Aluminium profiles and shop fittings

Cost-effective turnkey solutions

By coordinating design, production and powder coating, we reduce handling and lead times, resulting in competitive prices and high delivery precision.

Contact us

Do you need reliable powder coating for your next project? Call +46 (0)35-15 13 30 or email info@eica.se and we’ll get back to you with a tailored proposal