Robot welding as part of our “design to finished product” concept

At EICA, robot welding is part of our customised, high-quality production. With a welding robot configured for MAG welding, welding booths for MIG/MAG and TIG, and an integrated sheet-metal production facility, we take responsibility from design drawing to finished, assembled and inspected product.

Robot welding is always linked to our complete subcontract manufacturing flow - laser cutting, punching, bending, welding, surface treatment and assembly – with a focus on stainless steel, aluminium and mild steel in small to medium series.

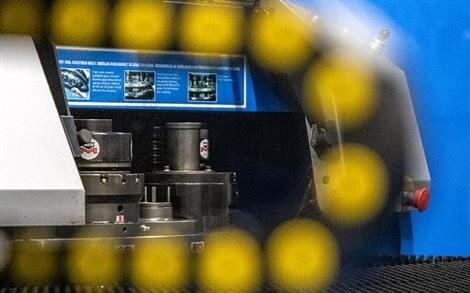

Robot welding in our production facility in Halmstad

In our facility we gather the key processes for sheet, tube, and wire. Here you will find fibre laser cutting, punching, press brakes, welding booths for MIG/MAG and TIG, as well as our welding robot configured for MAG welding. Together, these resources allow us to complement traditional welding with robot welding whenever repetitive joints and series of production are in focus.

Robot welding is particularly suitable when similar parts recur from series to series, and the same welding operation can be programmed into the flow. In those cases, the welding robot can work side by side with our welders in the booths, while we maintain the flexibility required for prototypes and special solutions.

From design drawing to robot-welded product

Customised production to match your requirements

For us, customised production is exactly what it sounds like: high-quality manufacturing is entirely based on the customer’s requirements. In technical terms, this is subcontract manufacturing. We prepare design drawings based on your descriptions or architect’s drawings, or work from your finished documentation if you prefer. From there, we build a production flow in which robot welding is included whenever it is the right choice for the assignment.

Our subcontract manufacturing flow

In principle, our production flow looks like this:

- Design drawing

- Laser cutting

- Punching

- Sheet bending

- Pressing

- Machining

- Welding

- Grinding

- Surface treatment

- Assembly

- Final inspection

In the welding step, we can combine TIG/MAG welding in booths with robot welding in our welding robot. In this way, we use robot welding where it creates the most value, while more complex or one-off parts are handled in our welding booths. Once the products leave welding, they can move on to grinding, surface treatment and assembly before final inspection.

Subcontract manufacturing for small to medium series

Our production facility is tailored to small to medium series. This means that we manufacture everything from single, laser-cut parts to complete products. Robot welding is therefore not a stand-alone service, but part of the complete solution we offer within subcontract manufacturing.

By combining our welding robot with laser cutting, press braking, welding and powder coating, we can create everything from hygiene-critical details to robust chassis in stainless steel, aluminium and mild steel. Having the entire chain under one roof allows us to keep lead times short, provide traceable quality and deliver products that are ready to use directly to the end customer.

When robot welding is the right choice at EICA

Robot welding is a good option when you:

- want to gather sheet-metal processing, welding, surface treatment and assembly with a single supplier

- have recurring parts where the same welding operation is repeated in series

- need components in stainless steel, aluminium or mild steel with consistent quality

- value welded parts that are included in a quality-assured and traceable production flow.

As a customer, you benefit from our experience as a family-owned company since 1957, our production facility with a welding robot, and our established working methods from design drawing to final inspection. Robot welding then becomes a tool to make the overall solution even more efficient – not an isolated process step.

Contact us about robot welding and subcontract manufacturing

Do you need a partner who can combine our welding robot with laser cutting, press braking, welding, powder coating and assembly? Get in touch with us at EICA in Halmstad. You can easily send a request for a quotation via the form on our website or contact us directly by phone or e-mail. Together we review your drawings and develop a solution that matches your requirements for quality, function, and delivery reliability.