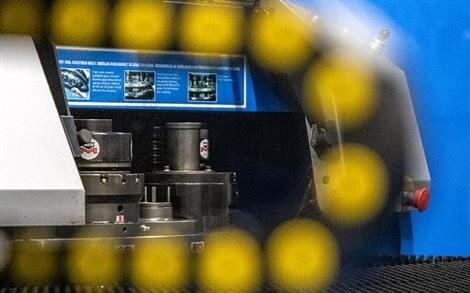

Punching – precision and flexibility from EICA

Since 1957, EICA has combined craftsmanship and modern technology in Halmstad. Our punching with a Finn-Power machine delivers clean cuts and consistent tolerances in stainless steel, aluminium and mild steel. The result is parts that fit perfectly into your designs – whether for patient furniture or advanced industrial components.

Machine Park that secures capacity

- Finn-Power punching machine for small to medium series

- Seamless changeover between punching and laser cutting thanks to an integrated production flow

- Complementary press braking, TIG/MAG welding and in-house powder coating for a finished product under one roof

Process flow from drawing to finished part

- Design – Our engineers optimize drawings for efficient punching and minimal scrap.

- Punching – the tools punch exactly according to the NC program for high repeatability.

- Post-processing – bending, CNC machining, welding and grinding.

- Surface finish – powder coating in our own facility, followed by assembly and final inspection.

Advantages of EICA’s punching

- High precision – Prima Power technology gives detailed accuracy that reduces the need for rework.

- Short lead times – the entire chain is located in our factory, which makes planning efficient.

- Wide range of materials – stainless steel for hygiene requirements, aluminium for low weight, mild steel for cost-effective designs.

- Environment & quality – documented policies ensure responsible production and continuous improvement.

Typical applications

- Operating and assistance tables, trolleys and other patient-near furniture

- Shop fittings, chassis and special parts in stainless or powder-coated sheet metal

- Prototypes and short production run where flexibility and rapid changeover are critical

Request a quote for punching

Do you need a partner that delivers precise punching with full traceability and reliable deliveries? Contact our team in Halmstad and we will quickly prepare a quote and show how our complete solution creates value for your project.

EICA – family-owned quality and precision in every punched part.